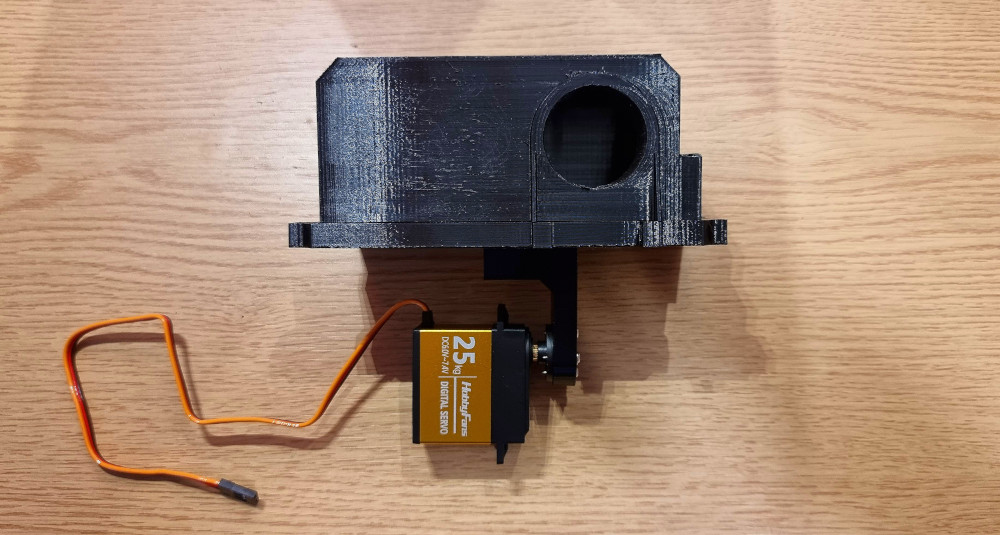

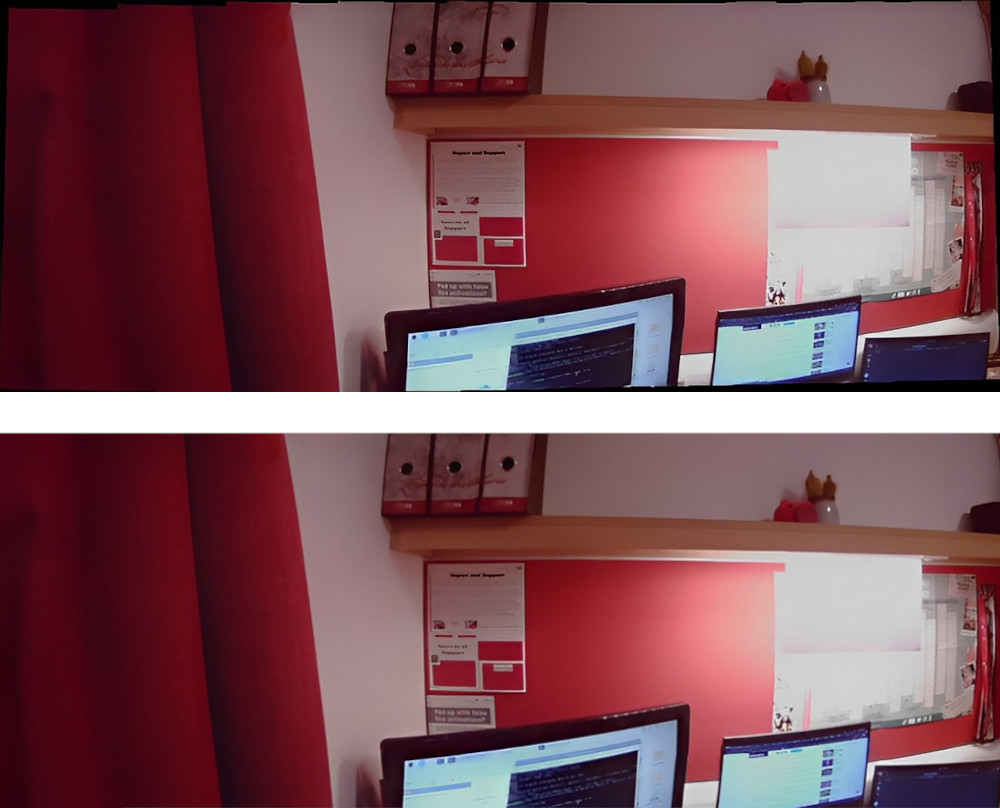

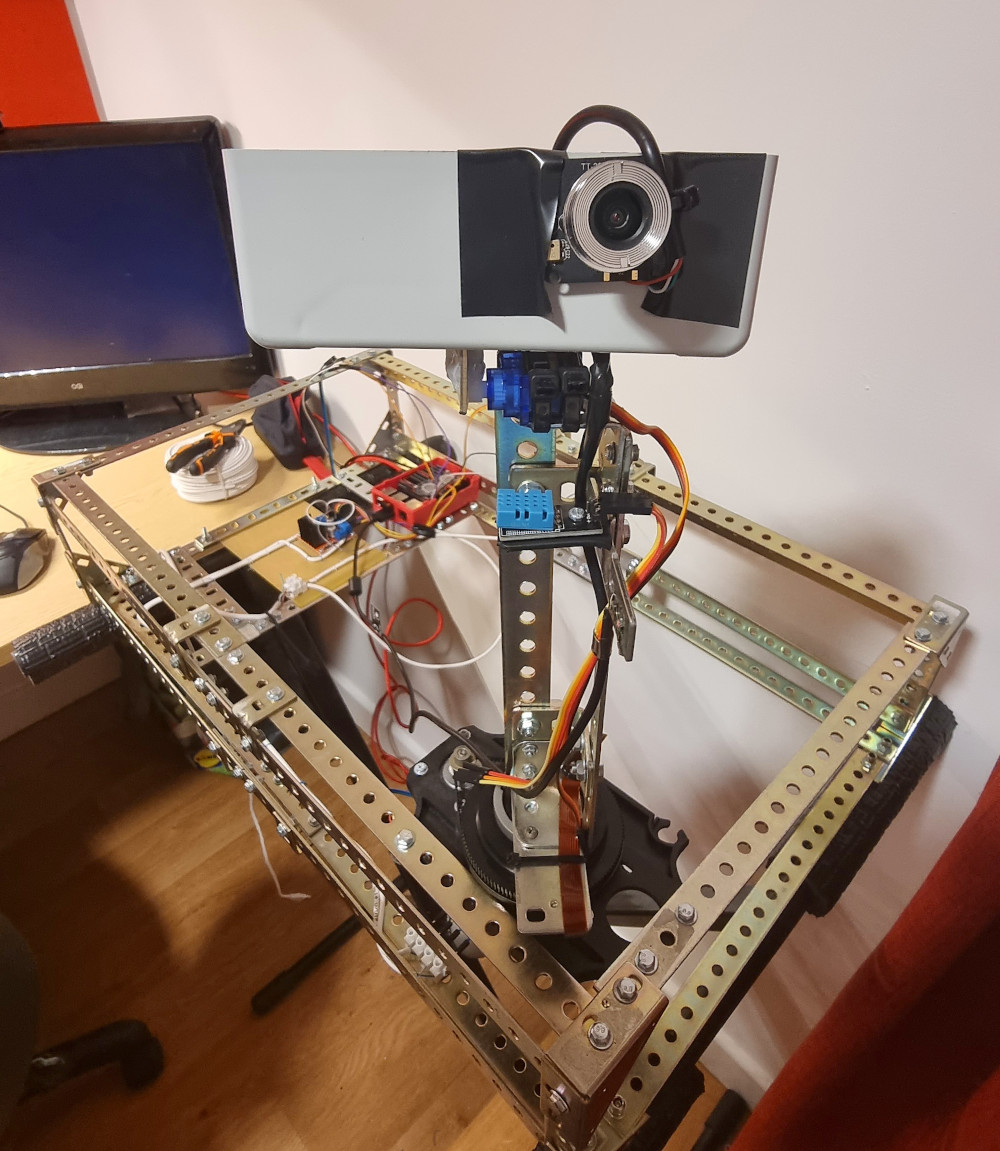

The camera housing of Imager's first version (last update 08/09/2022) was completely renewed by substituting all components with 3D printed parts. The structure is now pivoted on an "L" shaped piece and tilt rotation is done using a servo motor. This choice was made to ensure a precise movement using angles or radiants, instead of steps. Since the camera housing is not heavy, there is no need to use a stepper motor, so a high-torque servo motor has been implemented.

- [Hours of work: 1h]

- [People involved: Giorgio]