What's new on Continuity Rover?

I'm constantly working on Continuity, taking photos, videos and general notes on (almost) every new thing. If you want to be up to date with what's new, this is the right place!

Four legs balancing and exercises

Over the spring, from the beginning of March until the end of May, I focused on balancing Continuity. I tried many different approaches to gain experience and acquire critical thinking in selecting the best one.

- The first one is probably the most complex and common in robot control systems: Proportional Integral Derivative control, or PID. The balancing algorithm was working fine, as can be seen from this video. The PID control is not fine-tuned, but even without doing it, I immediately noticed something I didn't like: motors were weakening approaching the desired position, and losing torque. This behaviour is not normal and it might be caused by an incorrect setup of the power distribution system. Additionally, the servo motors were sometimes rotating to undesired positions, I guess due to overlapping signals (?), causing damage to the mechanical structure of the legs.

Transitioning to 6061 Aluminium

Watch: 1st attempt CNC machining Continuity's parts

Watch: 1st attempt CNC machining Continuity's parts

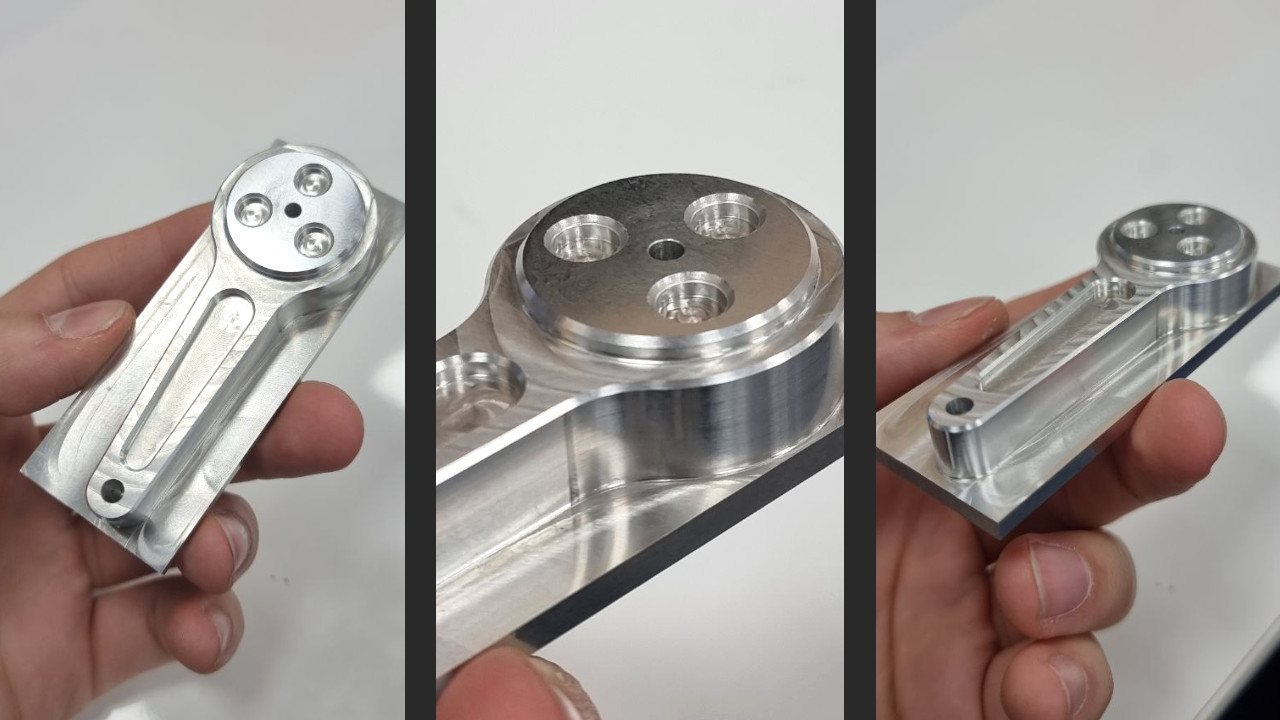

Continuity is currently crafted from 3D-printed PLA plastic, a good material in terms of prototyping flexibility, allowing easy modifications and adjustments. However, as we delve deeper into the mechanical demands, the limitations of PLA become apparent. Achieving structural strength requires high infill or an increase of the external wall count, yet this proves challenging for smaller, intricate parts, where PLA's fragility under load becomes a concern. With the assistance of Edinburgh Napier University's Mechanical Workshop technicians, we are embarking on a transformation. All structural components are undergoing a shift from PLA to robust 6061 Aluminium. This transition necessitates a complete redesign: I used Blender to 3D-model all the pieces, but differently from a 3D printer, CNC machines don't like STL files. To bridge the gap between Blender's polygon-based designs and CNC machines' preference for STEP files, I opted for FreeCad, aligning with my philosophy of using an open-source approach. The photo showcases one of the two top links for Continuity's legs, machined as a test using a CNC machine. The result is good, but not as good as it will be on the actual finished version.

Joypad integration

During the last few weeks of testing, I integrated a joypad into Continuity's control methods. This was done to simplify testing on the robot, improving precision and making things a bit more fun when it comes to having a quick demo available to show to people (this happened multiple times, in the past few weeks). I chose to connect a PS3 joypad using the comprehensive features offered by the "Gamepad" GitHub repository. This repository not only simplifies the process but also provides users with multiple joypad configurations, catering to diverse testing needs. In an initial trial, I focused on controlling the Remote Sensing Mast (RSM), a pivotal element of the rover that comes with two degrees of freedom: azimuth rotation and elevation. The RSM serves critical functions such as capturing photos, and panoramic images and facilitating autonomous navigation by aligning with the direction of movement. Subsequent tests focused on legs extension and other general movements, all executed seamlessly through joypad control. While these tests may appear useless given Continuity's ultimate autonomous functionality, being able to control the robot in a user-friendly way is actually extremely important for something that I'm working on aside. I'm trying to develop a simulation framework using Blender, the same open-source software I used for 3D modelling Continuity. Blender is capable of running rigid body simulations and being able to interface them with a Python script might allow me to use it as a real-time simulation tool. More updates will follow on this topic.

Standing on four legs!

After three months of testing Continuity's front legs only, I'm excited to share that the walking rover has taken a giant leap forward. I've just rolled out an update, bringing the two rear legs into action. This development is a game-changer because now I can dive into real 4-legs-balancing tests, exploring pitch and roll axes movements, along with trying out various walking gaits and manoeuvres. As of now, Continuity is equipped with 8x 25 Kg Servo Motors, each thirsting for 5-7 volts and drawing 1-2 Amps. The entire body is currently made out of 3D-printed PLA, but I've got big plans for the next version: several structural parts of the body will be converted into a sleek carbon fiber structure. The mobility system, aka the legs, is also in for an upgrade, transitioning to a robust aluminium CNC machining.

Front linkage update

Until the day of this post writing, the front and rear upper linkages of the leg were connected to the motors using aluminium flanges. Generally speaking, this component is great but performs poorly if an overhung stress is applied to the motor shaft, causing vibrations that tend to increase after intense testing of the leg. To (hopefully) fix the problem, I changed the design, substituting the flange with an aluminium bracket that can be secured to the motor shaft using small set screws. Additionally, this design increases the contact area between metal and plastic, improving the force distribution.

This configuration has been tested by running the same tests performed with the previous design. Results show that not only the vibrations are reduced (as well as the chance that screws get unscrewed due to vibrations), but also improve the stability of the leg when it was tested sideways and upside down.