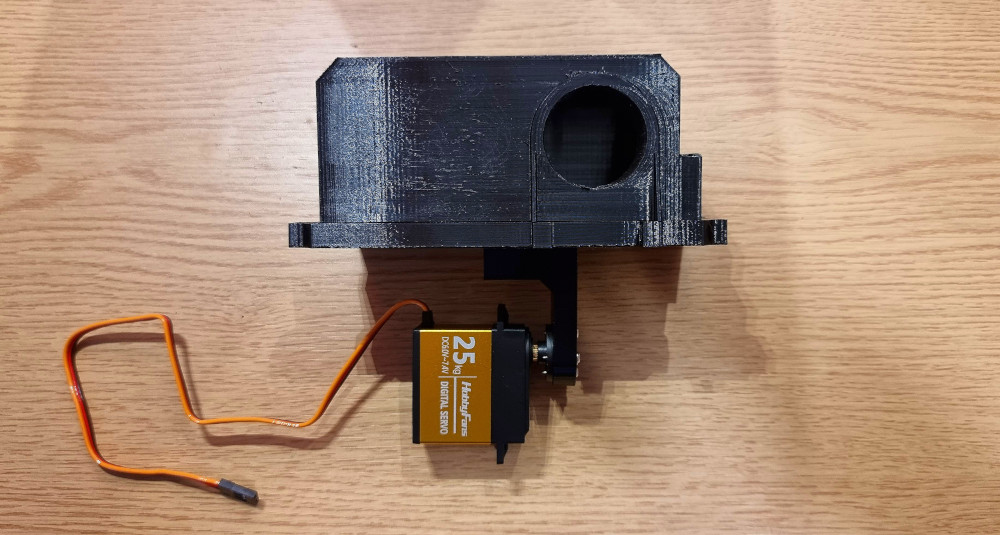

The first component of the Rocker-Bogie Suspension System has been 3D printed and assembled! The "Rocker" joint is split into two subassemblies and required a total of 18 hours of printing. After inserting four 6mm thick bolts, the structure is rock-steady!

- [Hours of work: 1h]

- [People involved: Giorgio]

![![enter image description here][1]](https://www.computerangels.net/mimas/content/images/20221017120850-03102022.jpg)